#Dairy Processing Equipment Industry Size

Explore tagged Tumblr posts

Text

Dairy Processing Equipment Market Outlook for Forecast Period (2023 to 2030)

The Global Dairy Processing Equipment Market size is expected to grow from USD 10834.56 million in 2022 to USD 16754.16 million by 2030, at a CAGR of 5.6% during the forecast period (2023-2030).

Growing the dairy processing equipment market across the globe due to the high preference for the packaged and nutritional dairy products by the consumers. The application of dairy processing equipment to produce numerous products such as processed milk, cream, yogurt, butter, and others. In addition, the key drivers of this market include growth in dairy production and switching in taste & preferences by the consumers. Increasing the health consciousness and demand for healthy products with low fat and cholesterol, low sugar, and new taste and flavor among the consumers, growing the market rapidly. Furthermore, growth in the incorporation of milk products in daily diet owing to high nutritive value will turn the market size. Changing dietary patterns by the consumers and demand for a product such as cheese, cream, and yogurt for making nutritious dishes may boost the demand for dairy processing equipment.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/15815

Leading players involved in the Dairy Processing Equipment Market include:

SPX FLOW Inc, Tetra Laval International S.A., GEA Group, Van Den Heuvel Dairy, Food Equipment Dairy, Krones AG, Alfa Laval Corporates, John Bean Technologies Corporation, IDMC Ltd., Scherjon Dairy Equipment Holland B.V., Coperion GmbH., IMA Industria Machine Automatiche SPA, Paul Mueller Company, Feldmeier Equpment Inc., Caloris Engineering LLC and other Major Players.

The latest research on the Dairy Processing Equipment market provides a comprehensive overview of the market for the years 2023 to 2030. It gives a comprehensive picture of the global Dairy Processing Equipment industry, considering all significant industry trends, market dynamics, competitive landscape, and market analysis tools such as Porter's five forces analysis, Industry Value chain analysis, and PESTEL analysis of the Dairy Processing Equipment market. Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years. The report is designed to help readers find information and make decisions that will help them grow their businesses. The study is written with a specific goal in mind: to give business insights and consultancy to help customers make smart business decisions and achieve long-term success in their particular market areas.

If You Have Any Query Dairy Processing Equipment Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/15815

Segmentation of Dairy Processing Equipment Market:

By Product Type

Membrane Filtration Equipment

Homogenizers

Separators

Mixing and Blending Equipment

Pasteurizers

Churning Equipment

Evaporators and Dryers

Other

By Operation

Automatic

Semi-Automatic

By Application

Milk Powders

Cream

Processed Milk

Cheese

Protein Concentrates

Yogurt

Other

An in-depth study of the Dairy Processing Equipment industry for the years 2023–2030 is provided in the latest research. North America, Europe, Asia-Pacific, South America, the Middle East, and Africa are only some of the regions included in the report's segmented and regional analyses. The research also includes key insights including market trends and potential opportunities based on these major insights. All these quantitative data, such as market size and revenue forecasts, and qualitative data, such as customers' values, needs, and buying inclinations, are integral parts of any thorough market analysis.

Market Segment by Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

Reasons for Acquiring this Report:

1. Strategic Decision-Making for Government Leaders and Politicians:

Gain insights into the global Dairy Processing Equipment Market Growth 2023-2030 market revenues at global, regional, and national levels until 2030. Assess and strategize market share based on comprehensive analysis, enabling informed decision-making. Identify potential markets for exploration and expansion.

2. Informed Decision-Making for Professionals and Product Developers:

Access a detailed breakdown of the Dairy Processing Equipment Market Growth 2023-2030 market worldwide, including product variations, use cases, technologies, and final consumers. Allocate resources effectively by anticipating demand patterns for emerging products. Stay ahead in product development by understanding market dynamics and consumer preferences.

3. Strategic Planning for Sales Managers and Market Stakeholders:

Utilize market breakdowns to target specific segments, optimizing sales strategies. Address challenges and capitalize on expansion opportunities highlighted in the report. Mitigate threats effectively with a comprehensive understanding of market risks.

4. Comprehensive Understanding for Executives:

Analyze primary drivers, challenges, restrictions, and opportunities in the global Laboratory Clothes market. Develop effective strategies by gaining insights into market dynamics. Allocate resources based on a thorough understanding of market conditions.

5. Competitive Intelligence:

Obtain a detailed analysis of competitors and their key tactics in the Dairy Processing Equipment Market Growth 2023-2030. Plan market positioning based on a comprehensive understanding of the competitive landscape. Stay ahead by learning from competitors’ strengths and weaknesses.

6. Accurate Business Forecasting:

Evaluate the accuracy of global Dairy Processing Equipment Market Growth 2023-2030 business forecasts across regions, major countries, and top enterprises. Make data-driven decisions with confidence, minimizing risks associated with inaccurate forecasts. Stay ahead of industry trends by aligning business strategies with reliable forecasts.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=15815

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyse extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1047

Email: [email protected]

#Dairy Processing Equipment#Dairy Processing Equipment Market#Dairy Processing Equipment Market Size#Dairy Processing Equipment Market Share#Dairy Processing Equipment Market Growth#Dairy Processing Equipment Market Trend#Dairy Processing Equipment Market segment#Dairy Processing Equipment Market Opportunity#Dairy Processing Equipment Market Analysis 2022#US Dairy Processing Equipment Market#Dairy Processing Equipment Market Forecast#Dairy Processing Equipment Industry#Dairy Processing Equipment Industry Size#china Dairy Processing Equipment Market#UK Dairy Processing Equipment Market

0 notes

Text

Dairy Processing Equipment Market Outlook for Forecast Period (2023 to 2030)

The Global Dairy Processing Equipment Market size is expected to grow from USD 10834.56 million in 2022 to USD 16754.16 million by 2030, at a CAGR of 5.6% during the forecast period (2023-2030).

Growing the dairy processing equipment market across the globe due to the high preference for the packaged and nutritional dairy products by the consumers. The application of dairy processing equipment to produce numerous products such as processed milk, cream, yogurt, butter, and others. In addition, the key drivers of this market include growth in dairy production and switching in taste & preferences by the consumers. Increasing the health consciousness and demand for healthy products with low fat and cholesterol, low sugar, and new taste and flavor among the consumers, growing the market rapidly. Furthermore, growth in the incorporation of milk products in daily diet owing to high nutritive value will turn the market size. Changing dietary patterns by the consumers and demand for a product such as cheese, cream, and yogurt for making nutritious dishes may boost the demand for dairy processing equipment.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/15815

Leading players involved in the Dairy Processing Equipment Market include:

SPX FLOW Inc, Tetra Laval International S.A., GEA Group, Van Den Heuvel Dairy, Food Equipment Dairy, Krones AG, Alfa Laval Corporates, John Bean Technologies Corporation, IDMC Ltd., Scherjon Dairy Equipment Holland B.V., Coperion GmbH., IMA Industria Machine Automatiche SPA, Paul Mueller Company, Feldmeier Equpment Inc., Caloris Engineering LLC and other Major Players.

The latest research on the Dairy Processing Equipment market provides a comprehensive overview of the market for the years 2023 to 2030. It gives a comprehensive picture of the global Dairy Processing Equipment industry, considering all significant industry trends, market dynamics, competitive landscape, and market analysis tools such as Porter's five forces analysis, Industry Value chain analysis, and PESTEL analysis of the Dairy Processing Equipment market. Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years. The report is designed to help readers find information and make decisions that will help them grow their businesses. The study is written with a specific goal in mind: to give business insights and consultancy to help customers make smart business decisions and achieve long-term success in their particular market areas.

If You Have Any Query Dairy Processing Equipment Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/15815

Segmentation of Dairy Processing Equipment Market:

By Product Type

Membrane Filtration Equipment

Homogenizers

Separators

Mixing and Blending Equipment

Pasteurizers

Churning Equipment

Evaporators and Dryers

Other

By Operation

Automatic

Semi-Automatic

By Application

Milk Powders

Cream

Processed Milk

Cheese

Protein Concentrates

Yogurt

Other

An in-depth study of the Dairy Processing Equipment industry for the years 2023–2030 is provided in the latest research. North America, Europe, Asia-Pacific, South America, the Middle East, and Africa are only some of the regions included in the report's segmented and regional analyses. The research also includes key insights including market trends and potential opportunities based on these major insights. All these quantitative data, such as market size and revenue forecasts, and qualitative data, such as customers' values, needs, and buying inclinations, are integral parts of any thorough market analysis.

Market Segment by Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

Reasons for Acquiring this Report:

1. Strategic Decision-Making for Government Leaders and Politicians:

Gain insights into the global Dairy Processing Equipment Market Growth 2023-2030 market revenues at global, regional, and national levels until 2030. Assess and strategize market share based on comprehensive analysis, enabling informed decision-making. Identify potential markets for exploration and expansion.

2. Informed Decision-Making for Professionals and Product Developers:

Access a detailed breakdown of the Dairy Processing Equipment Market Growth 2023-2030 market worldwide, including product variations, use cases, technologies, and final consumers. Allocate resources effectively by anticipating demand patterns for emerging products. Stay ahead in product development by understanding market dynamics and consumer preferences.

3. Strategic Planning for Sales Managers and Market Stakeholders:

Utilize market breakdowns to target specific segments, optimizing sales strategies. Address challenges and capitalize on expansion opportunities highlighted in the report. Mitigate threats effectively with a comprehensive understanding of market risks.

4. Comprehensive Understanding for Executives:

Analyze primary drivers, challenges, restrictions, and opportunities in the global Laboratory Clothes market. Develop effective strategies by gaining insights into market dynamics. Allocate resources based on a thorough understanding of market conditions.

5. Competitive Intelligence:

Obtain a detailed analysis of competitors and their key tactics in the Dairy Processing Equipment Market Growth 2023-2030. Plan market positioning based on a comprehensive understanding of the competitive landscape. Stay ahead by learning from competitors’ strengths and weaknesses.

6. Accurate Business Forecasting:

Evaluate the accuracy of global Dairy Processing Equipment Market Growth 2023-2030 business forecasts across regions, major countries, and top enterprises. Make data-driven decisions with confidence, minimizing risks associated with inaccurate forecasts. Stay ahead of industry trends by aligning business strategies with reliable forecasts.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=15815

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyse extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1047

Email: [email protected]

#Dairy Processing Equipment#Dairy Processing Equipment Market#Dairy Processing Equipment Market Size#Dairy Processing Equipment Market Share#Dairy Processing Equipment Market Growth#Dairy Processing Equipment Market Trend#Dairy Processing Equipment Market segment#Dairy Processing Equipment Market Opportunity#Dairy Processing Equipment Market Analysis 2022#US Dairy Processing Equipment Market#Dairy Processing Equipment Market Forecast#Dairy Processing Equipment Industry#Dairy Processing Equipment Industry Size#china Dairy Processing Equipment Market#UK Dairy Processing Equipment Market

0 notes

Text

Global Dairy Processing Equipment Expected To Reach USD 15020 Million By The Year 2028

Growing demand for packaged and nutritious dairy products by consumers is driving the global market for dairy processing equipment. the use of dairy processing machinery to create a variety of goods, including processed milk, cream, yoghurt, butter, and others. The expansion of the dairy industry and customer shifts in taste and preferences are also important market factors. The market is expanding quickly because to rising customer demand for healthy products that are reduced in sugar, fat, and cholesterol, as well as having novel flavours and tastes. Additionally, a rise in the consumption of milk products would change the market size due to their high nutritional value.

Read More: https://introspectivemarketresearch.com/reports/dairy-processing-equipment-market/

#Global Dairy Processing Equipment Market#Dairy Processing Equipment size#Dairy Processing Equipment industry#Dairy Processing Equipment trend

0 notes

Text

Milton Orr looked across the rolling hills in northeast Tennessee. “I remember when we had over 1,000 dairy farms in this county. Now we have less than 40,” Orr, an agriculture adviser for Greene County, Tennessee, told me with a tinge of sadness.

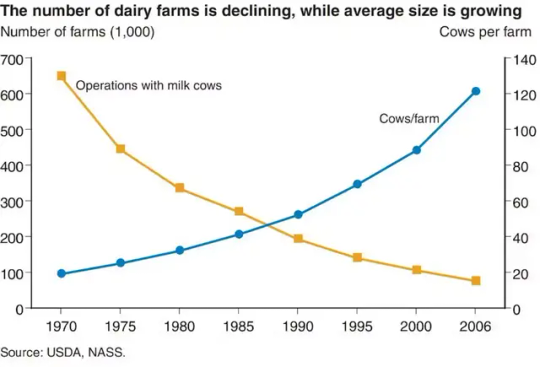

That was six years ago. Today, only 14 dairy farms remain in Greene County, and there are only 125 dairy farms in all of Tennessee. Across the country, the dairy industry is seeing the same trend: In 1970, more than 648,000 US dairy farms milked cattle. By 2022, only 24,470 dairy farms were in operation.

While the number of dairy farms has fallen, the average herd size—the number of cows per farm—has been rising. Today, more than 60 percent of all milk production occurs on farms with more than 2,500 cows.

This massive consolidation in dairy farming has an impact on rural communities. It also makes it more difficult for consumers to know where their food comes from and how it’s produced.

As a dairy specialist at the University of Tennessee, I’m constantly asked: Why are dairies going out of business? Well, like our friends’ Facebook relationship status, it’s complicated.

The Problem with Pricing

The biggest complication is how dairy farmers are paid for the products they produce.

In 1937, the Federal Milk Marketing Orders, or FMMO, were established under the Agricultural Marketing Agreement Act. The purpose of these orders was to set a monthly, uniform minimum price for milk based on its end use and to ensure that farmers were paid accurately and in a timely manner.

Farmers were paid based on how the milk they harvested was used, and that’s still how it works today.

Does it become bottled milk? That’s Class 1 price. Yogurt? Class 2 price. Cheddar cheese? Class 3 price. Butter or powdered dry milk? Class 4. Traditionally, Class 1 receives the highest price.

There are 11 FMMOs that divide up the country. The Florida, Southeast, and Appalachian FMMOs focus heavily on Class 1, or bottled, milk. The other FMMOs, such as Upper Midwest and Pacific Northwest, have more manufactured products such as cheese and butter.

For the past several decades, farmers have generally received the minimum price. Improvements in milk quality, milk production, transportation, refrigeration, and processing all led to greater quantities of milk, greater shelf life, and greater access to products across the US. Growing supply reduced competition among processing plants and reduced overall prices.

Along with these improvements in production came increased costs of production, such as cattle feed, farm labor, veterinary care, fuel, and equipment costs.

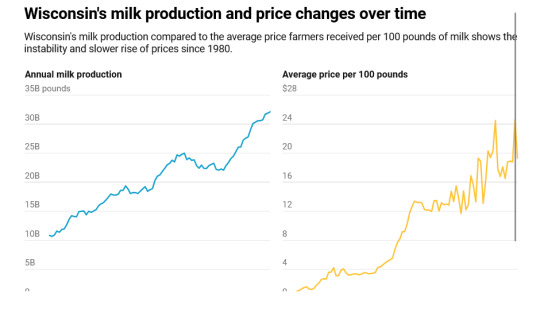

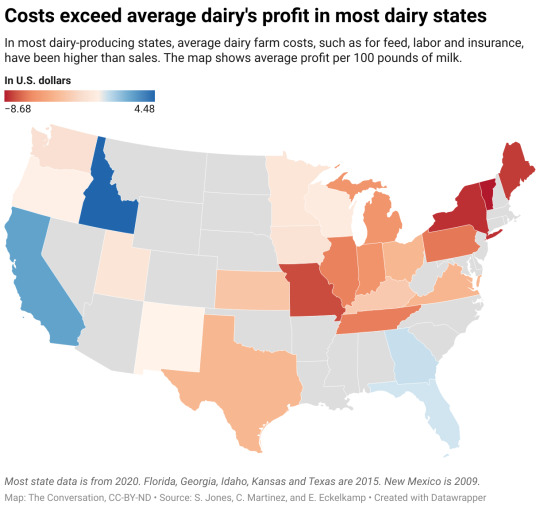

Researchers at the University of Tennessee in 2022 compared the price received for milk across regions against the primary costs of production: feed and labor. The results show why farms are struggling.

From 2005 to 2020, milk sales income per 100 pounds of milk produced ranged from $11.54 to $29.80, with an average price of $18.57. For that same period, the total costs to produce 100 pounds of milk ranged from $11.27 to $43.88, with an average cost of $25.80.

On average, that meant a single cow that produced 24,000 pounds of milk brought in about $4,457. Yet, it cost $6,192 to produce that milk, meaning a loss for the dairy farmer.

More efficient farms are able to reduce their costs of production by improving cow health, reproductive performance, and feed-to-milk conversion ratios. Larger farms or groups of farmers—cooperatives such as Dairy Farmers of America—may also be able to take advantage of forward contracting on grain and future milk prices. Investments in precision technologies such as robotic milking systems, rotary parlors, and wearable health and reproductive technologies can help reduce labor costs across farms.

Regardless of size, surviving in the dairy industry takes passion, dedication, and careful business management.

Some regions have had greater losses than others, which largely ties back to how farmers are paid, meaning the classes of milk, and the rising costs of production in their area. There are some insurance and hedging programs that can help farmers offset high costs of production or unexpected drops in price. If farmers take advantage of them, data shows they can functions as a safety net, but they don’t fix the underlying problem of costs exceeding income.

Passing the Torch to Future Farmers

Why do some dairy farmers still persist, despite low milk prices and high costs of production?

For many farmers, the answer is because it is a family business and a part of their heritage. Ninety-seven percent of US dairy farms are family owned and operated.

Some have grown large to survive. For many others, transitioning to the next generation is a major hurdle.

The average age of all farmers in the 2022 Census of Agriculture was 58.1. Only 9 percent were considered “young farmers,” age 34 or younger. These trends are also reflected in the dairy world. Yet, only 53 percent of all producers said they were actively engaged in estate or succession planning, meaning they had at least identified a successor.

How to Help Family Dairy Farms Thrive

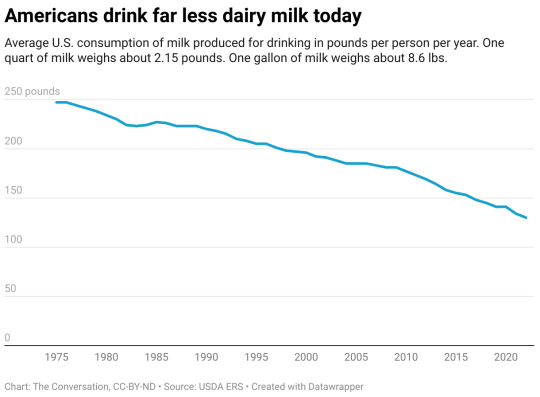

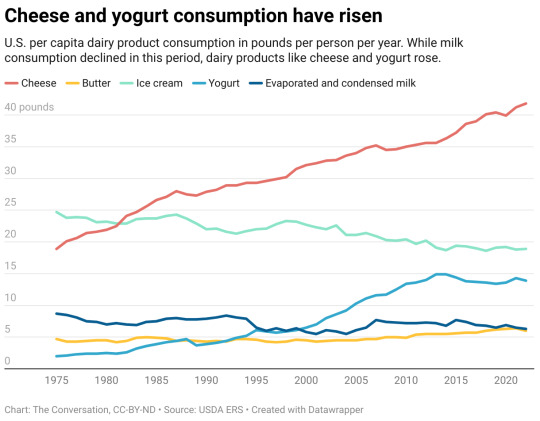

In theory, buying more dairy would drive up the market value of those products and influence the price producers receive for their milk. Society has actually done that. Dairy consumption has never been higher. But the way people consume dairy has changed.

Americans eat a lot, and I mean a lot, of cheese. We also consume a good amount of ice cream, yogurt, and butter, but not as much milk as we used to.

Does this mean the US should change the way milk is priced? Maybe.

The FMMO is currently undergoing reform, which may help stem the tide of dairy farmers exiting. The reform focuses on being more reflective of modern cows’ ability to produce greater fat and protein amounts; updating the cost support processors receive for cheese, butter, nonfat dry milk, and dried whey; and updating the way Class 1 is valued, among other changes. In theory, these changes would put milk pricing in line with the cost of production across the country.

The US Department of Agriculture is also providing support for four Dairy Business Innovation Initiatives to help dairy farmers find ways to keep their operations going for future generations through grants, research support, and technical assistance.

Another way to boost local dairies is to buy directly from a farmer. Value-added or farmstead dairy operations that make and sell milk and products such as cheese straight to customers have been growing. These operations come with financial risks for the farmer, however. Being responsible for milking, processing, and marketing your milk takes the already big job of milk production and adds two more jobs on top of it. And customers have to be financially able to pay a higher price for the product and be willing to travel to get it.

33 notes

·

View notes

Text

Manufacturer of Cold Storage Room in Gujarat

Saputo Process Engineering Pvt. Ltd. Is a Manufacturer of Cold Storage Room in Gujarat

Our Manufacturer Unit is in Ahmedabad, Gujarat, India.

Saputo Process Engineering Pvt. Ltd. is a trusted manufacturer of cold storage rooms in Gujarat, offering top-quality, energy-efficient, and customizable cold storage solutions for various industries.

With years of experience in the industry, we design, manufacture, and install cold storage rooms that meet the highest standards of quality, durability, and performance.

Our cold storage rooms are ideal for industries such as food processing, pharmaceuticals, dairy, and more, providing the perfect environment for preserving perishable goods.

Why Choose Saputo Process Engineering Pvt. Ltd. for Cold Storage Rooms?

Customizable Solutions: We offer custom-designed cold storage rooms tailored to meet your specific requirements, whether for temperature, size, or functionality.

Expert Installation and After-Sales Support: We offer complete installation services and ongoing support to ensure your cold storage room operates efficiently and reliably.

High-Quality Materials: We use durable, energy-efficient materials such as insulated panels and cold storage refrigeration units to ensure optimal temperature maintenance and energy savings.

Advanced Technology: Our cold storage rooms are equipped with state-of-the-art refrigeration systems that provide precise temperature control, ensuring reliability and efficiency.

Applications of Cold Storage Rooms:

Food Storage Pharmaceutical Storage Dairy Products Chemical Storage Floral Storage

Can the cold storage room be customized in size?

Yes, we offer full customization in size, design, temperature range, and other features to fit your specific storage needs.

Do you offer after-sales support for cold storage rooms?

Yes, we offer comprehensive after-sales support, including maintenance, servicing, and troubleshooting for your cold storage room. We are committed to ensuring the long-term efficiency and performance of our systems.

Saputo Process Engineering Pvt. Ltd. Is a Manufacturer of Cold Storage Room in Gujarat and We Provide Cold Storage Room in Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Anand, Gandhinagar, Bharuch, Morbi, Vapi, Valsad, Junagadh, Nadiad, Mehsana, Porbandar, Godhra, Navsari, Surendranagar, Patan, Amreli, Palanpur, Modasa, Dahod, Gandhidham, Bhuj, Ankleshwar, Kalol, Sanand, Halol, Kadi, Khambhat, Jetpur, Kutch, Mundra, Morbi, Rajpipla, Dwarka, Dholka, Gandharpur, Bhachau, Chotila, Dhandhuka, Umargam, Padra, Jhagadia, Kalol, Savli, Palghar, Godhra, Vallabh Vidyanagar, Mandvi, Halvad, Balasinor, Nandesari, Pardi, Karamsad.

Contact us today for more information, pricing, and availability.

0 notes

Text

Top 5 Advantages of Using Super Duplex Steel S32750 Pipes & Tubes in Industrial Applications

Introduction :

Nascent Pipe & Tubes is a renowned manufacturers and suppliers of Exceptionally Super Duplex Steel Pipes & Tubes. We have been a piece of this industry for a long time and our momentous thing is being used for a surprisingly long time. We have been serving Pipes & Tubes needs of perpetual current clients with our unequaled things.

Product Overview :

These have high molybdenum and chromium content in it. Other than these SS grades offer unmatched use confirmations in its game plan. This makes these reasonable for fundamentally acidic present day work processes. Work processes that utilization acidic and formic hurting track down these Pipes & Tubes essential. They offer the overall insistence from isolating pondering inorganic acids, especially chlorides.

Specification of Super Duplex Steel S32750 Pipes & Tubes :

Super Duplex Steel S32750 is a high-performance alloy made from a combination of austenitic and ferritic stainless steel, commonly referred to as a duplex stainless steel. It is specifically designed to offer excellent resistance to corrosion, high strength, and good weldability. The typical chemical composition of S32750 includes:

Chromium (Cr): 24-26%

Nickel (Ni): 6-8%

Molybdenum (Mo): 3-5%

Manganese (Mn): 1-2%

Silicon (Si): 0.8%

Nitrogen (N): 0.24-0.32%

Iron (Fe): Balance (usually 50-60%)

Key properties include:

Yield Strength (Rp0.2): ≥ 550 MPa

Tensile Strength (Rm): ≥ 800-1000 MPa

Elongation (A5): ≥ 25% (for 50 mm gauge length)

Hardness: 250-300 HV (Vickers Hardness)

Physical Properties:

Density: ~7.8 g/cm³

Melting Point: 1300–1350°C

Thermal Conductivity: 14 W/mK at 100°C

Modulus of Elasticity: 200 GPa

Dimensional Range:

Pipe size: From ½" to 24" (varies with standards)

Wall thickness: Can range from 1mm to 40mm

Tube size: Available in various forms, including seamless, welded, and extruded.

Applications of Super Duplex Steel S32750 Pipes & Tubes :

Due to its outstanding corrosion resistance, strength, and durability, Super Duplex Steel S32750 is widely used in various industries, including:

Oil & Gas Industry:

Subsea equipment, risers, pipelines, valves, and pumps where high strength and resistance to pitting, crevice, and stress corrosion cracking are critical.

Chemical Processing:

Pipelines, heat exchangers, and reactors for handling aggressive chemicals, including acids and chlorides.

Marine & Offshore:

Construction of offshore platforms, shipbuilding, and desalination plants. S32750's high resistance to seawater corrosion makes it an ideal choice for marine environments.

Power Generation:

Used in cooling systems, heat exchangers, and other critical components where resistance to chloride stress corrosion cracking is required.

Food and Beverage Industry:

Equipment in food processing, beverage plants, and dairy industry that requires high resistance to corrosion and hygienic standards.

Pharmaceutical & Biotech Industries:

Due to its non-reactive nature, it is used in applications where high standards of cleanliness and corrosion resistance are necessary.

Conclusion :

Super Duplex Steel S32750 pipes and tubes represent a sophisticated solution for applications where both high strength and superior corrosion resistance are essential. Their unique combination of ferritic and austenitic microstructures provides them with exceptional resistance to corrosion, pitting, crevice, and stress corrosion cracking, making them a versatile material for harsh and demanding environments.

#Super Duplex Steel S32750 Pipes & Tubes#Super Duplex Steel S32750 Pipes & Tubes Manufacturers#Super Duplex Steel S32750 Pipes & Tubes Suppliers#Super Duplex Steel S32750 Pipes & Tubes Stockists#Super Duplex Steel S32750 Pipes & Tubes Exporters#Super Duplex Steel S32750 Pipes & Tubes Manufacturers In India#Super Duplex Steel S32750 Pipes & Tubes Suppliers In India#Super Duplex Steel S32750 Pipes & Tubes Stockists In India#Super Duplex Steel S32750 Pipes & Tubes Exporters In India

0 notes

Text

Applications of High Shear Mixers: How Manufacturers Cater to Different Industries

High shear mixers are essential tools in various industries, providing efficient mixing, emulsifying, and dispersing capabilities. With advanced engineering and tailored features, leading high shear mixer manufacturers design equipment that meets the unique demands of each industry. From pharmaceuticals to cosmetics and food processing, high shear mixers enhance production by ensuring uniformity, efficiency, and quality in processing diverse materials. In this article, we explore the key applications of high shear mixers across industries and how manufacturers optimize their designs to cater to specific needs.

1. Pharmaceuticals

In the pharmaceutical industry, high shear mixers play a crucial role in creating stable emulsions, dispersions, and even coatings. They are commonly used in the production of tablets, ointments, and suspensions. Leading high shear mixer manufacturers understand the critical requirements for hygiene, precision, and consistency in this sector. As a result, they provide mixers with features like stainless steel construction, GMP compliance, and easy cleaning mechanisms. This ensures that pharmaceutical products are produced under safe and controlled conditions, meeting rigorous quality standards.

2. Food and Beverage

For the food and beverage industry, high shear mixers are invaluable for tasks such as homogenizing, emulsifying, and dispersing ingredients. These mixers are used to produce a wide range of products, including sauces, dressings, dairy products, and beverages. Top high shear mixer manufacturers equip these mixers with food-grade materials and customizable speed controls to achieve desired textures and uniformity. They also integrate temperature control systems to help maintain the quality of sensitive ingredients. These features ensure that food products meet both safety standards and consumer expectations for taste and texture.

3. Cosmetics and Personal Care

In the cosmetics and personal care sector, high shear mixers are essential for creating products with consistent textures and stability, such as lotions, creams, and makeup products. Since product consistency and appearance are crucial for market appeal, high shear mixer manufacturers design mixers capable of breaking down particles to achieve a smooth and uniform finish. Additionally, these mixers are often designed to minimize aeration, which is essential for creating smooth creams and gels. High shear mixers tailored for cosmetics often feature temperature control and high-speed blending capabilities to maintain product integrity during mixing.

4. Chemical Industry

In the chemical industry, high shear mixers are used to blend, emulsify, and disperse a range of chemicals, including adhesives, resins, and polymers. Because chemical processes often involve corrosive materials, high shear mixer manufacturers provide mixers made with corrosion-resistant materials like stainless steel and advanced coatings. They also offer customizable features, including high-torque motors and variable mixing speeds, allowing the equipment to handle even the most challenging materials. This versatility is key in producing consistent chemical compounds required in applications like adhesives and coatings.

5. Paints and Coatings

For paints and coatings, achieving a uniform blend of pigments and other components is essential for color consistency and durability. High shear mixers are commonly used to disperse pigments and ensure an even particle size distribution. High shear mixer manufacturers catering to this industry often focus on providing mixers with high-speed settings and powerful blades to achieve the required level of dispersion. These mixers are also equipped with advanced control systems that allow operators to fine-tune mixing parameters, ensuring consistent product quality batch after batch.

6. Biotechnology

The biotechnology field requires precise mixing equipment to handle sensitive biological materials, including cell cultures, enzymes, and proteins. High shear mixers in biotech applications must be able to achieve specific shear rates without damaging the biological components. Manufacturers serving the biotechnology industry often provide high shear mixers with gentle mixing options and sterile designs. This allows for safe and effective processing of bio-based materials in applications such as cell lysis, enzyme production, and vaccine formulation.

7. Adhesives and Sealants

In the production of adhesives and sealants, high shear mixers are used to create homogeneous blends of polymers, fillers, and solvents. These mixers must be capable of handling high-viscosity materials. High shear mixer manufacturers serving the adhesives industry often design mixers with powerful motors and specialized blades to manage thick formulations. Additionally, they may provide custom designs that allow for quick cleaning and material changeovers, which are essential for manufacturers working with multiple adhesive formulations.

Customization: How Manufacturers Tailor Mixers to Industry Needs

Understanding that each industry has unique requirements, high shear mixer manufacturers offer various customization options to ensure their equipment meets the specific needs of different sectors. Some of these customizations include:

Material Selection: Food-grade, pharmaceutical-grade, and corrosion-resistant materials to match industry standards.

Speed and Torque Control: Adjustable speed settings and high-torque options for versatile mixing capabilities.

Temperature Control: Integrated heating or cooling systems to maintain product quality during mixing.

Automation and Digital Control: Advanced controls and programmable settings to optimize efficiency and consistency.

Cleanability: Easy-to-clean designs for industries with stringent hygiene requirements, such as pharmaceuticals and food processing.

Conclusion

High shear mixers are indispensable across a wide array of industries, from pharmaceuticals and cosmetics to chemicals and food processing. Each industry relies on high shear mixers to achieve efficient, consistent, and high-quality production. By offering customized features and robust designs, high shear mixer manufacturers enable businesses to meet industry-specific demands, ensuring that each product is processed to the highest standards.

Whether it’s a food-grade mixer for emulsifying sauces or a pharmaceutical-grade mixer for creating uniform suspensions, high shear mixer manufacturers play a vital role in enhancing production processes across sectors.

0 notes

Text

Bakery Equipments Suppliers in Bangalore: Essential Tools for Your Baking Business

Bangalore, a city known for its diverse culinary culture, has seen a surge in the popularity of bakeries offering everything from traditional Indian sweets to Europeanstyle pastries. To keep up with the demands of the modernday baking industry, bakeries require advanced and highquality equipment. For any bakery, whether a startup or an established business, choosing the right "Bakery Equipments Suppliers in Bangalore" can be a gamechanger. Quality equipment enhances efficiency, ensures consistency, and helps maintain high standards, making it vital to partner with reliable suppliers who understand the unique needs of bakeries.

Key Bakery Equipment Needed for a Successful Bakery

A successful bakery depends heavily on the quality of its equipment. The right tools can simplify processes, improve quality, and save time. Here’s a look at some essential pieces of equipment that bakery businesses in Bangalore rely on to create delicious products:

1. Ovens: Ovens are the backbone of any bakery, and choosing the right one is crucial. Convection ovens, deck ovens, and rotary ovens are popular choices in Bangalore. Convection ovens are known for their versatility, even heating, and are ideal for baking a wide range of products, from cakes to bread. Deck ovens offer high heat and are perfect for crusty bread and pastries, while rotary ovens are excellent for largescale production. Working with established bakery equipment suppliers in Bangalore can help bakeries select ovens best suited for their products and production scale.

2. Mixers: Mixers come in various sizes, from small countertop models to large industrial ones, and are indispensable for dough and batter preparation. Planetary mixers are popular for handling different types of batters, while spiral mixers are ideal for kneading dough. Bakery equipments suppliers in Bangalore offer a range of mixers that cater to specific needs, ensuring consistent product quality and efficiency.

3. Proofing Cabinets: Proofing, or allowing dough to rise, is a delicate process that requires controlled temperature and humidity. Proofing cabinets are designed to maintain ideal conditions, promoting consistent rising and quality texture. Many bakery equipments suppliers in Bangalore offer advanced proofing cabinets that streamline this essential process, making it easier to achieve consistent results even with large volumes.

4. Refrigeration Units: Bakeries need reliable refrigeration for ingredients like dairy, fruits, and fillings that require cool storage to maintain freshness. Equipment such as blast chillers and refrigerators helps store ingredients at the right temperature, preserving flavor and texture. Suppliers in Bangalore offer highquality refrigeration units that help reduce spoilage and ensure food safety, essential for bakeries managing large inventories.

5. Dough Sheeters and Dividers: Dough sheeters are vital for producing consistent layers in pastries and bread, while dough dividers ensure equal portions for products like buns and rolls. With a sheeter, bakers can roll dough to the desired thickness quickly and evenly, which is crucial for items like croissants and puff pastries. Many bakery equipments suppliers in Bangalore provide options that allow bakers to automate these tasks, saving time and reducing labor costs.

6. Display Units: Once the products are ready, showcasing them attractively is essential. Display units such as counters, refrigerated showcases, and open racks allow bakeries to display products at optimal temperatures, enticing customers with an appealing presentation. Bakery equipments suppliers in Bangalore offer customizable display options that match the ambiance of the bakery while ensuring food safety.

Choosing Reliable Bakery Equipments Suppliers in Bangalore

Bangalore hosts several suppliers specializing in bakery equipment, but finding the right partner is crucial to a bakery's success. Here are some key considerations when selecting bakery equipment suppliers in Bangalore:

Product Range: Reliable suppliers offer a wide variety of equipment to meet different baking needs, from basic tools to advanced machinery. This versatility ensures that bakeries, whether small or large, can find equipment that fits their specific requirements.

Quality and Durability: Quality equipment lasts longer, performs better, and requires fewer repairs. Trusted bakery equipments suppliers in Bangalore provide durable, highperformance machines, sourced from reputable manufacturers that understand the demands of the baking industry.

Customer Support and Maintenance Services: Equipment maintenance is essential to prevent downtime and costly repairs. Suppliers who offer strong customer support and maintenance services can help keep a bakery running smoothly. Many suppliers in Bangalore offer maintenance packages, periodic checkups, and quick repair services, minimizing disruptions and ensuring smooth operations.

Customization Options: Every bakery has unique needs, so the ability to customize equipment is a big plus. Many top bakery equipments suppliers in Bangalore provide customized solutions that meet specific requirements, from display units that align with branding to ovens with adjustable settings for unique recipes.

Pricing and Financing: While quality equipment can be expensive, many suppliers in Bangalore offer financing options, making it easier for bakeries to invest in the best tools without stretching their budget. Competitive pricing and flexible payment plans are attractive features that many reliable suppliers offer.

The Future of Bakery Equipment in Bangalore

With Bangalore’s food industry expanding, the demand for highquality bakery equipment will likely continue to grow. Technological advancements, such as energyefficient ovens, automated dough processors, and smart refrigeration, are expected to shape the future of bakery equipment. By partnering with trusted bakery equipments suppliers in Bangalore, businesses can access these innovations, enhancing productivity and staying competitive in an evolving market.

Conclusion

For bakeries to succeed, investing in highquality equipment is essential. From ovens and mixers to refrigeration units and display counters, each piece plays a critical role in producing delicious, highquality products. By choosing reliable bakery equipments suppliers in Bangalore, bakery owners can ensure their operations run smoothly, helping them achieve consistency, quality, and efficiency. With the right equipment and supplier partnership, bakeries in Bangalore are wellequipped to thrive and serve up treats that keep customers coming back.

#bakery equipments suppliers in bangalore#commercial cooking equipments in bangalore#bakery oven manufacturers in bangalore

0 notes

Text

Farm Management Software Industry Size, Trends, Statistics and Analysis Report, 2030

The global farm management software market was valued at USD 3.30 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 16.2% from 2023 to 2030. This growth is primarily driven by the increasing adoption of cloud computing for real-time farm data management, which allows for better decision-making and resource optimization. Farm management software leverages Information Communication Technology (ICT), including the Internet of Things (IoT) and big data analytics, to help farmers overcome challenges related to energy, water, and labor shortages. Additionally, FMS addresses environmental concerns, animal welfare, and fertilizer usage, all of which can negatively impact agricultural productivity.

One of the key factors contributing to the growth of the FMS market is the increased adoption of remote sensing technology in the agriculture sector. Drones and Geographic Information Systems (GIS) have made it easier to use remote sensing devices to capture detailed images of crops and farmland. These images can be analyzed to detect crop water stress, monitor weeds and crop diseases, classify crop species, and map soil properties. Several open-source remote sensing tools are available, including Quantum GIS Semi-Automatic Classification Plugin (SCP), Optical and Radar Federated Earth Observation (ORFEO) toolbox, Opticks, and PolSARPro, which further support the adoption of this technology.

Gather more insights about the market drivers, restrains and growth of the Farm Management Software Market

The use of site-specific crop management (SSCM) is expected to become more prevalent, as it allows farmers to optimize pesticide use, improve crop yields, and make more informed management decisions. Advanced farm management software equipped with data analytics capabilities can process both historical and real-time data to generate predictive models. These models help farmers forecast crop performance under different environmental conditions, providing insights into areas like weather patterns, soil quality, and crop health. By offering these insights, FMS can help farmers make informed decisions about fertilization, pest control, and irrigation. Phenotyping, which involves the analysis of crop traits such as nitrogen depletion and soil pH levels, plays a critical role in understanding crop growth under different environmental conditions, further supporting the efforts to boost crop yields.

Agriculture Type Segmentation Insights:

The farm management software market is segmented based on agriculture type into precision farming, livestock monitoring, smart greenhouses, and others, which include horticulture and fish farming. In 2022, the precision farming segment accounted for the largest share of the market at 43.5%, and it is expected to maintain its dominance throughout the forecast period.

Precision farming is a key driver of the FMS market due to its use of IoT and ICT to optimize resources and maximize yields. By measuring conditions within a field and adapting farming strategies accordingly, precision farming allows growers to control the amount of fertilizers applied to crops, leading to more efficient farming. Both hardware and software tools are used to analyze natural conditions such as soil moisture, temperature, and plant growth in specific fields, allowing for targeted interventions. Key applications of precision farming include yield monitoring, crop scouting, irrigation management, inventory management, and weather tracking. These technologies help farmers make better decisions to enhance crop production while reducing resource consumption.

Precision livestock monitoring is another growing area within farm management software. This technology provides real-time data on livestock health, productivity, and welfare, ensuring that animals are managed in a way that optimizes yield. As the size of dairy farms increases, technological advancements such as precision livestock monitoring are becoming increasingly important. Market players are focusing on launching new products that reduce the costs associated with livestock monitoring and management, making these technologies more accessible to farmers. Additionally, the rise in urban populations has driven growth in the smart greenhouse segment. Smart greenhouses are designed to provide optimal growing conditions for crops by using sensors and automated systems to monitor and adjust variables such as temperature, humidity, and light. This segment is expected to benefit from ongoing urbanization and the growing demand for locally sourced, fresh produce.

In summary, the farm management software market is growing rapidly due to the increasing adoption of advanced technologies that enable more efficient, data-driven agricultural practices. These technologies are helping farmers improve yields, reduce resource consumption, and address various challenges related to agriculture in today's environment.

Order a free sample PDF of the Farm Management Software Market Intelligence Study, published by Grand View Research.

#Farm Management Software Industry#Farm Management Software Market Research#Farm Management Software Market Forecast#Farm Management Software Market Overview

0 notes

Text

Farm Management Software Industry Trends, Size, Revenue And Top Key Players, 2030

The global farm management software market was valued at USD 3.30 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 16.2% from 2023 to 2030. This growth is primarily driven by the increasing adoption of cloud computing for real-time farm data management, which allows for better decision-making and resource optimization. Farm management software leverages Information Communication Technology (ICT), including the Internet of Things (IoT) and big data analytics, to help farmers overcome challenges related to energy, water, and labor shortages. Additionally, FMS addresses environmental concerns, animal welfare, and fertilizer usage, all of which can negatively impact agricultural productivity.

One of the key factors contributing to the growth of the FMS market is the increased adoption of remote sensing technology in the agriculture sector. Drones and Geographic Information Systems (GIS) have made it easier to use remote sensing devices to capture detailed images of crops and farmland. These images can be analyzed to detect crop water stress, monitor weeds and crop diseases, classify crop species, and map soil properties. Several open-source remote sensing tools are available, including Quantum GIS Semi-Automatic Classification Plugin (SCP), Optical and Radar Federated Earth Observation (ORFEO) toolbox, Opticks, and PolSARPro, which further support the adoption of this technology.

Gather more insights about the market drivers, restrains and growth of the Farm Management Software Market

The use of site-specific crop management (SSCM) is expected to become more prevalent, as it allows farmers to optimize pesticide use, improve crop yields, and make more informed management decisions. Advanced farm management software equipped with data analytics capabilities can process both historical and real-time data to generate predictive models. These models help farmers forecast crop performance under different environmental conditions, providing insights into areas like weather patterns, soil quality, and crop health. By offering these insights, FMS can help farmers make informed decisions about fertilization, pest control, and irrigation. Phenotyping, which involves the analysis of crop traits such as nitrogen depletion and soil pH levels, plays a critical role in understanding crop growth under different environmental conditions, further supporting the efforts to boost crop yields.

Agriculture Type Segmentation Insights:

The farm management software market is segmented based on agriculture type into precision farming, livestock monitoring, smart greenhouses, and others, which include horticulture and fish farming. In 2022, the precision farming segment accounted for the largest share of the market at 43.5%, and it is expected to maintain its dominance throughout the forecast period.

Precision farming is a key driver of the FMS market due to its use of IoT and ICT to optimize resources and maximize yields. By measuring conditions within a field and adapting farming strategies accordingly, precision farming allows growers to control the amount of fertilizers applied to crops, leading to more efficient farming. Both hardware and software tools are used to analyze natural conditions such as soil moisture, temperature, and plant growth in specific fields, allowing for targeted interventions. Key applications of precision farming include yield monitoring, crop scouting, irrigation management, inventory management, and weather tracking. These technologies help farmers make better decisions to enhance crop production while reducing resource consumption.

Precision livestock monitoring is another growing area within farm management software. This technology provides real-time data on livestock health, productivity, and welfare, ensuring that animals are managed in a way that optimizes yield. As the size of dairy farms increases, technological advancements such as precision livestock monitoring are becoming increasingly important. Market players are focusing on launching new products that reduce the costs associated with livestock monitoring and management, making these technologies more accessible to farmers. Additionally, the rise in urban populations has driven growth in the smart greenhouse segment. Smart greenhouses are designed to provide optimal growing conditions for crops by using sensors and automated systems to monitor and adjust variables such as temperature, humidity, and light. This segment is expected to benefit from ongoing urbanization and the growing demand for locally sourced, fresh produce.

In summary, the farm management software market is growing rapidly due to the increasing adoption of advanced technologies that enable more efficient, data-driven agricultural practices. These technologies are helping farmers improve yields, reduce resource consumption, and address various challenges related to agriculture in today's environment.

Order a free sample PDF of the Farm Management Software Market Intelligence Study, published by Grand View Research.

#Farm Management Software Industry#Farm Management Software Market Research#Farm Management Software Market Forecast#Farm Management Software Market Overview

0 notes

Text

RBD Chaff Cutter (Chara Katne Wali Machine): A Key Tool for Efficient Fodder Cutting

In the agricultural industry, efficient fodder preparation is essential for livestock farming. One of the most essential tools for farmers is the Chaff Cutter (commonly referred to as a chara katne wali machine). Designed for cutting straw or hay into small pieces, this machine ensures easy consumption by animals and improves the digestibility of the fodder.

Features of the RBD Chaff Cutter High Efficiency: The RBD Chaff Cutter is designed to handle large quantities of straw, grass, or hay, making it highly efficient for daily use on farms.

Durable Blades: Equipped with sharp, long-lasting blades, this machine ensures smooth cutting and precise size reduction of fodder.

Adjustable Output: The machine allows for customization of the cut size, making it adaptable to different types of fodder requirements for cows, buffaloes, goats, and other livestock.

Sturdy Build: Made from high-quality materials, the RBD Chaff Cutter is durable and resistant to wear and tear, ensuring it lasts for years under heavy use.

Easy to Operate: Even for farmers with limited technical experience, this machine is simple to operate, maintain, and clean.

Benefits of Using the Chara Katne Wali Machine Improves Livestock Nutrition: The machine cuts fodder into small, uniform pieces, making it easier for animals to chew and digest, leading to better nutrition and health.

Saves Time: Manual cutting of fodder is time-consuming and labor-intensive. The RBD Chaff Cutter automates the process, allowing farmers to save valuable time and effort.

Reduces Wastage: By cutting fodder evenly, this machine minimizes waste, ensuring that livestock consume a higher percentage of the feed provided.

Cost-Effective: Over time, the efficiency and time savings provided by the chaff cutter lead to reduced labor costs and better utilization of available fodder.

Applications of the RBD Chaff Cutter Dairy Farms: Ensures the preparation of balanced, nutritious fodder for cows and buffaloes.

Livestock Farms: Ideal for cutting hay and straw for goats, sheep, and other farm animals.

Agricultural Farms: Helps in the processing of agricultural residues such as corn stalks and sugarcane tops, turning waste into usable fodder.

Contact details

📞📞 +91-9694949030 📞📞 +91-9782949030

#ChaffCutter#CharaKatneWaliMachine#FodderCutter#LivestockFarming#RBDChaffCutter#FarmMachinery#FodderPreparation#AgricultureTools#EfficientFarming#DairyFarmTools#LivestockFeed#FodderProcessing

0 notes

Text

Milk Chilling Plant in Gujarat

Saputo Process Engineering Pvt. Ltd. Provides a Milk Chilling Plant in Gujarat. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Saputo Process Engineering Pvt. Ltd. Is one leading Manufacturers, Exporters and Supplier of Milk processing plant, Dairy Automation, Membrane, RMRD Equipment’s (VMST and HMST), Homogenizer, Ice cream Machine, Bulk Milk Cooler (Chiller Plant), Butter Processing System, Separator, HTST Milk Pasteurization Plant, Margarine Automatic Processing System, Evaporator, Milk Powder Plant (Spray Dryer), Cold Room, Crate Washers Machines, Paneer and Cheese Processing System, THE (Tube Heat Exchanger), Conveyor (Belt, Chain, and Roller), Processing-cum-Packing Line for Milk, Filtration Equipment, and CIP Systems. Saputo Process Engineering Pvt. Ltd. is dedicated to providing advanced milk chilling solutions that ensure optimal preservation and quality of milk. Our milk-chilling plants are designed to meet the needs of dairy producers while adhering to the highest industry standards. Features: Rapid Cooling: Our milk chilling plants utilize advanced cooling technology to quickly reduce the temperature of freshly collected milk, preventing bacterial growth and maintaining quality. Energy Efficiency: Designed with energy-efficient systems, our plants minimize energy consumption, reducing operational costs. Automated Controls: Equipped with user-friendly control systems, our chilling plants allow for easy monitoring and adjustments, ensuring consistent performance. Robust Construction: We design our plants with high-quality materials to withstand the rigors of daily operations and ensure long-lasting durability. Versatile Capacity: Available in various sizes, our milk chilling plants can accommodate different production scales, from small farms to large dairy operations. Hygienic Design: Complying with food safety standards, our chilling plants feature easy-to-clean surfaces and systems that prevent contamination. What is the primary function of a milk-chilling plant? A milk chilling plant rapidly cools freshly collected milk to prevent bacterial growth and maintain quality. How does the cooling process work? The chilling process uses refrigerants to absorb heat from the milk, quickly reducing its temperature to the desired level. What capacity options are available? We offer a range of capacities suitable for various dairy operations, from small to large-scale production. Are your milk-chilling plants customizable? Yes, we can customize our chilling plants to meet the specific needs and requirements of your dairy operation. Saputo Process Engineering Pvt. Ltd. Provide Milk Chilling Plant in Gujarat including locations like Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Anand, Gandhinagar, Bharuch, Morbi, Vapi, Valsad, Junagadh, Nadiad, Mehsana, Porbandar, Godhra, Navsari, Surendranagar, Patan, Amreli, Palanpur, Modasa, Dahod, Gandhidham, Bhuj, Ankleshwar, Kalol, Sanand, Halol, Kadi, Khambhat, Jetpur, Kutch, Mundra, Morbi, Rajpipla, Dwarka, Dholka, Gandharpur, Bhachau, Chotila, Dhandhuka, Umargam, Padra, Jhagadia, Kalol, Savli, Palghar, Godhra, Vallabh Vidyanagar, Mandvi, Halvad, Balasinor, Nandesari, Pardi, Karamsad. Contact us today for inquiries or to place an order! View Product: Click Here Read the full article

0 notes

Text

304 Stainless Steel Pipes in Industrial Applications

304 stainless steel is one of the most widely used and versatile materials in the industry, known for its exceptional corrosion resistance, high strength, and excellent durability. It is extensively utilized in various sectors, including construction, chemical processing, and food and beverage industries, where superior performance in challenging environments is crucial. As a leading Stainless Steel 304 Pipes Supplier, Metalloy International is committed to delivering premium-quality products to meet the needs of a broad range of industries.

Properties and Applications of 304 Stainless Steel Pipes

The unique properties of Stainless Steel 304 Pipe make it a preferred choice for demanding applications. It is an austenitic stainless steel with a high content of chromium and nickel, providing excellent resistance to oxidation and corrosion, even in harsh chemical environments. Additionally, Stainless Steel 1.4301 Pipe (as it is referred to under the European standard) offers high-temperature resistance, making it suitable for both low and high-temperature applications.

304 stainless steel pipes are widely used in:

Petrochemical industries

Food processing and dairy equipment

Heat exchangers

Pharmaceutical machinery

Marine environments

Our Stainless Steel 304 Seamless Pipes ensure a smooth surface finish, increased pressure tolerance, and excellent mechanical properties, making them ideal for fluid transportation and industrial piping systems.

Types of 304 Stainless Steel Pipes

At Metalloy International, we provide various types of SS 304 Pipes, designed to meet the specific requirements of different applications. These include:

ASME SA312 Stainless Steel TP304 Pipes Supplier: Manufactured to ASME SA312 standards, these pipes are suitable for high-temperature and high-pressure applications in industries like oil and gas.

ASTM A358 TP304 Stainless Steel EFW Pipes: These electric fusion welded pipes are known for their resistance to corrosion and stress cracking. They are particularly beneficial in industries requiring welded pipes of high strength and reliability.

SS 304 ERW Pipes: Our Electric Resistance Welded (ERW) pipes offer durability, flexibility, and corrosion resistance for a wide range of applications.

As a reputable Stainless Steel 304 Pipes Manufacturer, Metalloy International takes pride in providing top-quality products. Our SS 304 pipes are available in a wide variety of sizes, grades, and finishes to meet the needs of our clients.

Why Choose Metalloy International?

Metalloy International is a leading supplier and manufacturer of SS 304 Pipes. With years of experience in the stainless steel industry, we have built a reputation for delivering premium-quality products and excellent customer service. We ensure that all our products, including Stainless 304 Pipes, adhere to international quality standards and are thoroughly tested for durability and performance.

For more information on our extensive range of Stainless Steel 304 Pipes, visit Metalloy International.

Whether you need STAINLESS STEEL 304 PIPES SUPPLIER services or customized solutions for your projects, Metalloy International is your trusted partner in the industry.

#Stainless Steel 304 Pipes Supplier#Stainless Steel 1.4301 Pipe#Stainless Steel 304 Pipe#Stainless Steel 304 Seamless Pipes#SS 304 Pipes#ASME SA312 Stainless Steel TP304 Pipes Supplier#SS 304 pipes#Stainless Steel 304 Pipes Manufacturer#ASTM A358 TP304 Stainless Steel EFW Pipes#SS 304 ERW Pipes#SS 304 pipes Manufacturer#Stainless 304 Pipes#STAINLESS STEEL 304 PIPES SUPPLIER#SS 304 Pipes.

0 notes

Text

Stainless Steel Welded pipes manufacturers in India

Welded Pipes

Mangalam Worldwide is a leading manufacturer of premium quality stainless steel welded pipes and seamless pipes. Our pipes are available in different sizes and grades, tailored to meet the requirements of different industries

Mangalam has extensive manufacturing program for stainless steel welded pipes. Welded Pipes are widely used in Chemicals & Petrochemicals, Pharmaceuticals, Food & Beverage, Paper & Pulp and Marine industries etc.

Production program is according to main manufacturing standards like ASTM/ASME, EN and other international standards. Non standard welded pipes can be manufactured to order.

Outside Diameter: 1/2” NB to 6″ NB

Wall Thickness: Sch. 5s to Sch. 40s.

Supply Condition: Annealed & Pickled

Specifications: ASTM; ASME; DIN EN (German); JIS (Japan); Norsok, Gost etc.

Applications: Oil & Gas, Petrochemicals, Dairy Processing Equipment, Power Generation, Chemicals, Transportation (Aerospace, Automobiles, Railways), Pharmaceuticals & Medical Equipment, Defence, Mechanical & Plant Engineering, Liquefaction Projects, Food & Beverage Processing, Pressure Vessels, Marine Equipments, Pulp & Paper etc. Mangalam Worldwide is a leading manufacturer of premium quality welded pipes manufacturers in India

We are a multi location Fully Integrated Specialty Stainless Steel Mill.

A LEADER in Sustainable Stainless Steel manufacturing, we are A Fully Integrated Specialty Stainless Steel Mill. Based out of Ahmedabad, Gujarat, India, our production facilities are located at Halol, Changodar and Kapadvanj.

0 notes

Text

Fast and High-Quality Dairy Product Production with Mini Dairy Plant Machinery and Equipment

Efficient and high-quality production is essential in the ever-changing dairy industry. To keep up with the rising demand for high-quality, freshly-dairy products, small and medium-sized dairy companies require dependable, high-performance solutions. Milk Processing Plant and Machines for micro dairy plants come into play here, allowing for rapid, scalable, and high-quality milk production.

#Milk Processing Plant and Machines#Milk Processing Plant and Machines Manufacturers#Milk Processing Plant and Machines Suppliers#Milk Machines#Milk Processing Machines#Milk#Dairy Equipment#Dairy Machines#Dairy Machine Manufacturers

0 notes

Text

SS Industrial Storage Tanks: A Vital Component in Modern Industry

Stainless Steel (SS) Industrial Storage Tanks are an essential part of modern industry, serving as secure and reliable containers for storing a variety of liquids, gases, and chemicals. These tanks play a crucial role in industries such as food and beverage, pharmaceuticals, chemicals, oil and gas, and water treatment, where the storage of sensitive or hazardous materials requires durable, hygienic, and corrosion-resistant solutions.

This article explores the different types, applications, and benefits of SS industrial storage tanks, highlighting their importance in ensuring safe and efficient operations in various industries.

What Are SS Industrial Storage Tanks?

SS Industrial Storage Tanks are made from stainless steel, a material renowned for its strength, corrosion resistance, and hygienic properties. This layer protects the steel from corrosion, making it ideal for storing materials that are corrosive, reactive, or require strict hygiene standards.

SS tanks are available in various sizes and configurations, from small-scale containers for residential or commercial use to large, custom-built industrial tanks that can store thousands of gallons of liquid.

Types of SS Industrial Storage Tanks

Depending on the industry and specific application, different types of SS storage tanks are used. Each type is designed to address unique storage challenges, such as pressure control, temperature fluctuations, or the need for mixing substances.

Vertical Tanks: These tanks stand upright and are typically used for storing large volumes of liquids in factories or warehouses. Their vertical design allows for the efficient use of space, making them a popular choice in industrial settings.

Horizontal Tanks: Horizontal tanks are ideal for applications where vertical space is limited. They are often used in transportation or in situations where the tank needs to be placed beneath other equipment.

Jacketed Tanks: Jacketed tanks feature a double-walled design that allows for the heating or cooling of the material inside. These tanks are widely used in the food and beverage industry, where temperature control is critical, such as in brewing, dairy processing, or chemical manufacturing.

Pressure Tanks: Pressure tanks are built to withstand high-pressure environments, making them suitable for storing gases or liquids under pressure, like in chemical plants or oil refineries.

Mixing Tanks: These tanks are equipped with agitators or mixers that allow for the blending of substances. They are commonly used in industries such as pharmaceuticals, where precise mixing of ingredients is required.

Applications of SS Industrial Storage Tanks

Due to their versatility and reliability, SS industrial storage tanks are used in a wide range of industries.

Food and Beverage Industry: SS tanks are widely used in the food and beverage sector for storing liquids such as milk, juices, wine, and oils. The non-reactive and hygienic properties of stainless steel make it a safe choice for food-grade applications. In addition, these tanks are often used in the fermentation, pasteurization, and mixing processes.

Chemical Industry: The chemical industry often handles corrosive and hazardous materials that require robust and resistant storage solutions. Chemical storage Tanks are ideal for this purpose, as they can safely store chemicals, solvents, and acids without degrading.

Pharmaceutical Industry: In the pharmaceutical industry, maintaining sterile and contamination-free environments is essential. SS tanks are frequently used to store purified water, raw materials, and finished liquid medications, ensuring that products remain safe and uncontaminated.

Water Treatment: SS tanks are an important component in water treatment facilities, where they are used to store clean water, wastewater, or chemicals used in the purification process. Stainless steel's resistance to corrosion ensures a long service life in these harsh environments.

Oil and Gas Industry: In oil refineries and gas processing plants, SS tanks are used to store crude oil, refined petroleum products, and industrial gases. These tanks are designed to handle high-pressure and high-temperature conditions typical of the energy sector.

Benefits of SS Industrial Storage Tanks

The use of stainless steel in industrial storage tanks offers numerous advantages, contributing to their widespread adoption across industries. Key benefits include:

Corrosion Resistance: One of the primary reasons industries choose SS tanks is their ability to resist corrosion. Whether storing water, chemicals, or food products, stainless steel does not rust or corrode, even when exposed to harsh chemicals or extreme conditions.

Hygienic Properties: Stainless steel is a non-porous material, which means it does not harbor bacteria or mold. This makes SS tanks ideal for industries where cleanliness and hygiene are paramount, such as food production, pharmaceuticals, and cosmetics.

Durability: SS tanks are highly durable and can withstand extreme temperatures, pressure, and mechanical stress. This durability ensures a longer lifespan and fewer maintenance requirements compared to tanks made from other materials, such as plastic or mild steel.

Customizable: Stainless steel tanks can be easily customized to meet the specific needs of various industries. Whether a company requires a small tank for lab use or a massive industrial storage solution, SS tanks can be manufactured in a variety of shapes, sizes, and configurations.

Eco-Friendly: Stainless steel is 100% recyclable, making SS tanks an environmentally friendly option. At the end of their life cycle, SS tanks can be melted down and repurposed without losing their structural integrity or material properties.

Temperature and Pressure Resistance: Stainless steel’s ability to withstand high temperatures and pressures makes it suitable for a wide range of applications, including those in harsh environments like oil refineries or chemical plants.

Conclusion

MS SS Tanks are a critical asset in many industries, offering durability, safety, and flexibility in the storage of liquids, gases, and other materials. Whether it’s ensuring the hygiene of food products, safely storing hazardous chemicals, or maintaining the integrity of pharmaceuticals, stainless steel tanks provide an unmatched combination of strength, resistance to corrosion, and ease of maintenance.

With the growing focus on sustainability, SS tanks also present an eco-friendly solution, ensuring that industries can meet their operational needs while reducing environmental impact. As technology and manufacturing processes continue to evolve, stainless steel storage tanks will remain a cornerstone of industrial storage solutions across the globe.

0 notes